How to Source Injection Molding Services from China

The important meeting has recently finished, your new product has been approved, time is pressing, and funding is, to put it mildly, limited. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

Naturally, you agree. It seems sensible at first glance. The cost savings can be huge. Yet your thoughts are already spinning. You know the rumors, don’t you? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It feels like walking a thin line between big savings and total project failure.

But here’s the catch. Sourcing China injection molding doesn’t have to be a gamble. It’s no different from any structured project. And like any project, it succeeds or fails based on the process you follow. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Forget the horror stories. Let’s walk through a real-world playbook for getting it right.

Initial Step: Prepare Your Information

Before you mention “supplier” or browse Alibaba, organize your internal data. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You cannot expect overseas partners to interpret your unspoken requirements. It’s akin to asking someone to price-build “a structure” with no details. The responses you get will be all over the map, and none of them will be useful.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. This becomes the bedrock of your sourcing project.

What belongs in your RFQ?

Start with your 3D design files. They’re essential. Use standard formats such as STEP or IGS to ensure compatibility. This is the authoritative CAD geometry.

But 3D isn’t enough. Add comprehensive 2D plans. This details critical info missing from the 3D file. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Next up, material. Avoid generic terms like “Plastic.” Even “ABS” alone is too vague. Be explicit. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. What’s the reason? Because plastic grades vary by the thousands. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

They can offer alternatives, but you must provide the initial spec.

Finally, include the business details. State your EAU. You must specify if it’s a 1K-part tool or a 1M-part production run. Cavity count, tooling cost, and per-unit pricing depend on volume.

Finding the Right Supplier

Now that your RFQ is pristine. who gets your RFQ? Online sourcing is global but crowded. Finding suppliers is simple; finding quality ones is tough.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Use them to build a shortlist, not the final list. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

But don’t stop there. Think about engaging a sourcing agent. They do cost extra. But a good one has a vetted network of factories they trust. They are your person on the ground, navigating the language and cultural barriers. On your first run, this is like insurance. Consider it timeline insurance.

Also consider trade fairs. With budget permitting, Chinaplas or similar shows are invaluable. Meeting onsite is unbeatable. Hold samples, talk shop, and gauge professionalism firsthand. And don’t forget the oldest trick in the book: referrals. Consult trusted colleagues. Peer endorsements carry huge weight.

Shortlisting Serious Suppliers

After firing off that RFQ to a broad pool, bids begin to arrive. You’ll see ridiculously low offers and steep quotes. Now, sift through and shortlist 2–3 reliable candidates.

What’s the method? It blends technical checks with intuition.

First, look at their communication. Is their turnaround swift and concise? Is their English good enough for complex technical discussions? But the key: do they probe your RFQ? Top vendors will critique and inquire. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” This is a massive green flag. It shows they’re engaged and experienced. A “Sure, no issues” vendor often means trouble.

Next, dig into their technical capabilities. Get their tooling inventory. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. Don’t pick a micro-molding shop for large components.

Finally, inspect the factory. You can’t skip this. Just as you interview hires, audit suppliers. You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They dispatch an on-site auditor for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s the best few hundred dollars you will ever spend on your project.

From Digital File to Physical Part

You’ve selected your partner. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the real fun begins.

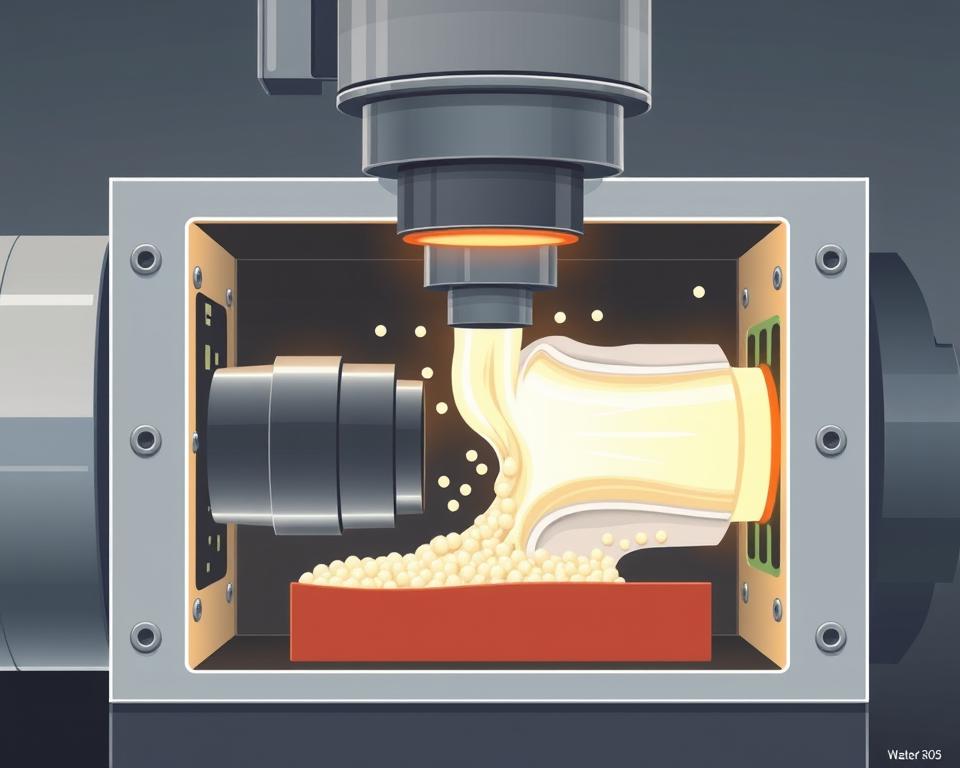

Your supplier’s first deliverable is a DFM analysis. Design for Manufacturability (DFM) is essential. It’s the engineering critique for moldability. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It becomes a joint effort. You iterate with their team to optimize the mold.

When you greenlight the DFM, they machine the mold. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are the very first parts off the new tool. It’s your test of success.

Be prepared: T1 samples are almost never perfect. This is normal! You’ll find minor defects, off-spec dimensions, or finish issues. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold company samples. You may repeat this cycle a few times. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is now the benchmark sample. You sign off, and it serves as the master quality reference.

Final Steps to Mass Production

Landing the golden sample is huge, yet the project continues. Now comes full-scale production. How do you maintain consistency for part 10,000?

Put a strong QC process in place. Typically, this means a pre-shipment audit. Use a third-party inspector again. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. You receive a full report with images and measurements. Once you sign off, you greenlight shipping and the last payment. This step saves you from a container of rejects.

Finally, think about logistics. Understand the shipping terms, or Incoterms. Does FOB apply, passing risk at the ship’s rail? Or EXW, shifting all transport to you? These choices hugely affect landed cost.

Overseas sourcing is a marathon. It hinges on strong supplier relations. See them as collaborators, not vendors. Clear communication, mutual respect, and a solid process are your keys to success. Certainly, it’s complex. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’ve got this.